|

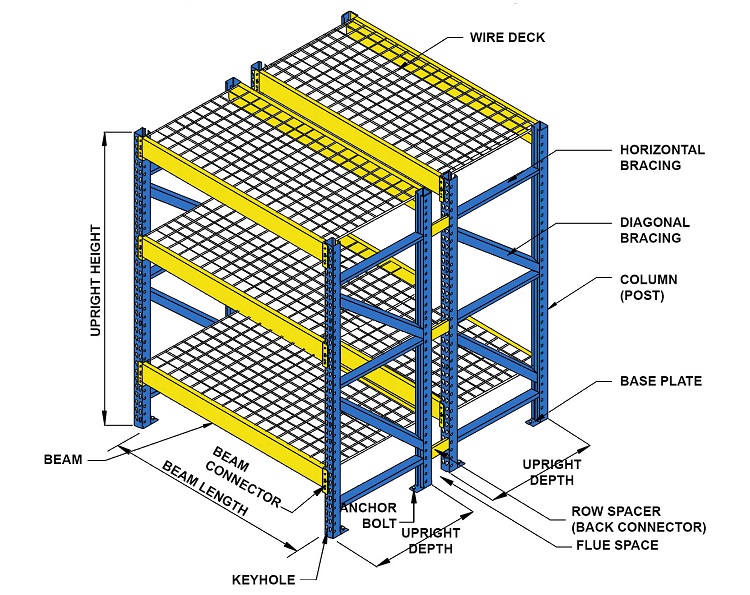

Components of a Pallet Rack System

Example of Pushback Pallet Racking

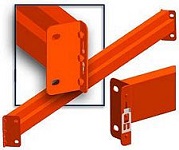

Just about all pallet rack manufacturers offer designs that are basically do the same things for their customers, although not all are engineered for the same amount of weight handling, and the connecting components are often not be the same. Each manufacturer has a slightly different beam-to-frame connector that differentiates them from the rest. There are a few common designs though that multiple manufacturers make fairly similar. Called the “teardrop” design, it has become the favorite and most common beam-to-frame connector choice. Multiple manufacturers have Teardrop Style Racking available.

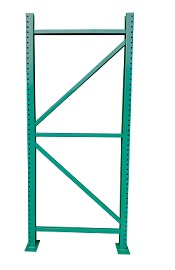

PALLET RACK UPRIGHT BEAMS

Pallet Rack Upright Beams (also called upright columns or uprights) have holes on the front face of the columns into which the pins of the horizontal bars connectors engage. These horizontal cross beams connect into the upright frames on both ends to create a shelf. Continue adding all of the shelves and it looks like a pallet rack.

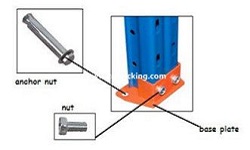

PALLET RACK BASE PLATES

An upright frame needs to have at least two baseplates which are used to anchor the pallet rack to the floor for stability. The size of the baseplate is based on seismic forces and the loads placed on the pallet rack. Engineers should check the design to make sure the proper baseplate is specified for the pallet racking.

PALLET RACK METAL SHIMS

Shims are used to make the pallet rack level. The size of the shims should match the size of the upright baseplate.

PALLET RACK HORIZONTAL BEAMS

Two pallet rack horizontal beams with a connector on either end are required to form one shelf.

PALLET SUPPORTS

Metal pallet supports (sometimes called cross bars), are used to help equal out the load. It supports the pallets between the beams, The typical setup has two crossbars beneath each pallet. Metal pallet supports are often used underneath the wire mesh decking to provide additional strength to the wire dec. The metal pallet supports may appear similar to 2 x 4s being used as supports but the metal pallet supports provide a great deal more strength and eliminate the fire hazard issue. Yes, they are more expensive than their wooden counterpart, but due to the increased load capacity and long term durability, they are a great investment. Crossbars are used to help equal out the load. It support pallets between the beams. The typical setup has two crossbars beneath each pallet load.

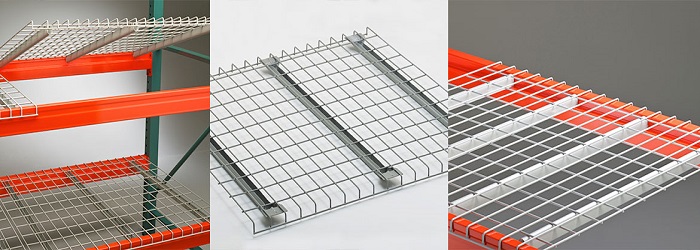

PALLET RACK WIRE DECKING

Wire Decking for pallet racks is also called wire shelving or wire decks. Wire decking is designed exclusively to provide users of pallet rack shelving the ability to store items on shelves without having to use a pallet. The wire mesh grid in pallet rack wire decking allows light to pass through and evenly disperse from ceiling to floor. Using wire mesh deck in pallet rack storage reduces shadows, resulting in brighter warehouses. Better distribution of existing lighting is proven to reduce accidents and increase stocking and picking efficiencies. Wire decking provides increased stability and protection to the pallet rack over conventional pallet support beams alone. Wire decking also increases the level of safety by reducing the risk of loss due to fire. In the event of fire, traditional solid decking materials like wood or plywood ignite and blocks water from getting to the fire. With wire decking, this problem is all but eliminated because water can easily pass through the mesh wire, allowing sprinklers access to flames. Wire deck has proven to be so successful at reducing losses due to fire that most local fire codes now require wire decking be used wherever indoor pallet rack storage is utilized. Wire decking is available in different protective coatings to choose from. Depending on the Pallet Rack environment you can choose from either painted, powder coated or galvanized wire decking.

PALLET RACK WOOD DECKING

If you are storing lightweight products, using 2 x 4s or 2 x 6s as wood decking is a good option. Also depending on the wood chosen, it can be one of the cheapest options. However, keep in mind wood may not provide adequate strength for your needs. If you are storing heavy pallets or heavy products, wood should not be considered an option. Another point against using wood for decking is that most buildings are inspected regularly by the Fire Marshall. The fire marshalls concern over wood decking being very flammable may keep you from even considering using wood decking.

There are many choices of decking for your pallet racks. Choice usually comes down to the intended use and municipal law.

PALLET RACK ROW SPACERS

Row spacers are used when pallet racks are back-to-back to provide a space between them. Row spacers also give the pallet racks additional strength and steadiness.

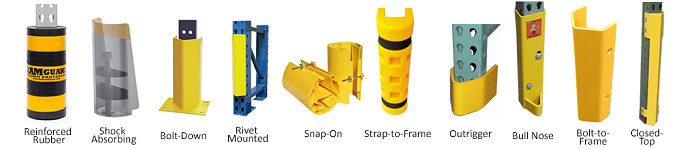

PALLET RACK COLUMN PROTECTORS | POST PROTECTORS | STRADDLE PROTECTORS

The bolt-on protector are accessories that help shield the pallet rack uprights, the Column protectors are simply extra protection from forklift impact damage.

PALLET RACK END OF ISLE GUARDS

End of Aisle Guards are either bolted to the racking or anchored to the floor to help prevent damage at the end of the aisle.

PALLET RACK ANCHOR BOLTS

For Safety, pallet racks are required to be anchored to the floor. The size, type and how deep the bolts must be put in the floor are all determined by local building codes or seismic engineered design.

Industrial Pallet Rack ships over 25 different manufacturers and types of racking to suit any need you may have. If we don’t have it, we can most likely locate it for you through our national dealer network. Need help identifying the manufacturer and style of racking you have? Click This Link To View Pallet Rack Manufacturer Identification Guide or simply pick up the phone and call (954) 205-4071.

Family owned and operated since 1993, our focus has always been helping our customers with Pallet Rack Identification,

Pallet Rack Design, Pallet Rack Additions and Pallet Rack Installation. We have tons of experience with new, and second hand or used pallet racking of all

types and brands. We have thousands of light and heavy duty beams, column uprights, decking of all types, small components and accessories available.

Our staff's trained, knowledgeable and ready to assist you. If you need to add-on or change the existing layout of your warehouse rack system we carry a wide

assortment of components and accessories to suit your needs. In stock and ready to ship, our pallet racks are sold in separate pieces. Sizes vary in height,

length, and depth. We can provide you with any type and the exact style of pallet racking you need.

For a FREE QUOTE call (954) 205-4071 or use the "Get A Quote Link" above to send us a note.

|

Want To Learn More About Pallet Racks? Click On Selections Below

|

|

Using any of the photographs on this website for commercial use is prohibited without permission from Industrial Pallet Rack® Inc.