Want To Learn About Other Types of Pallet Racking?

|

Why Cantilever Storage Racks?

Ideal for Long, Heavy, Unwieldy and Bulky Loads

|

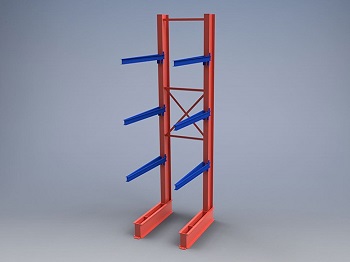

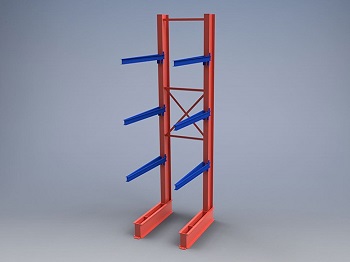

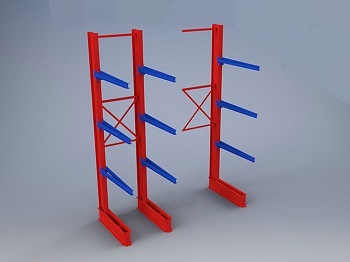

Industrial Pallet Rack Inc. sells a complete line of Cantilever Storage Racks which are ideal for storing tubes, bar stock, lumber, or other long, heavy,

unwieldy, or bulky loads. Rack single sided and double sided uprights are available. The cantilevers vertical columns are available from 8' to 20' and buyers are very pleased with the increased storage capacity. Both

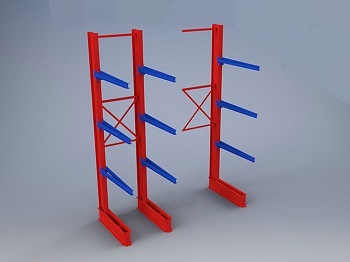

inclined and straight cantilever arms are available with an arm length of 12 inch to 60 inch. Two bases/columns, one brace set, and arms are required to make one free-standing starter unit. Additional sections can be added to starter

units by purchasing one additional base/column, one brace set, and another set of arms. All components are sold individually or as a complete package.

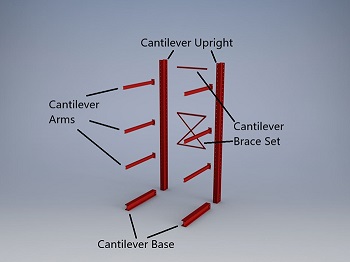

Starter Cantilever Rack Components

|

Starter Cantilever Rack

|

Starter Cantilever Rack + Add on Rack

|

We realize one size does NOT fit all. When you contact us to order a cantilever rack system, your support team member will listen to your needs, assess your challenges, and work with our design engineer to create a superior

storage solution specific to your situation. The size, shape and weight of your product, combined with the physical characteristics of your storage space and equipment, will drive the development of your unique solution. Our cantilever storage racks specifications eliminate the

possibility of deflection or sagging. As the optimal storage solution for lengthy or odd-shaped loads, cantilever racks easily hold lumber, tubes, fabric rolls, steel pipes, PVC, and other long objects. Choose a straight cantilever arm with the correct length and dimension to

safely store flat materials like lumber racks, or choose the correct length and dimensions in an inclined cantilever arm to safely store round items like steel piping.

Cantilever uses steel beams for the uprights, bases, and arms of the rack. Depending on the weight of your items

going on the racks, we choose either "Roll-Formed" or "structural I Beam" construction. Roll Formed cantilever is created using coiled sheet metal that is rolled into the necessary shape. A structural I Beam cantilever is more heavy-duty and has a higher capacity than Roll Formed cantilever.

The two styles are not interchangeable. Roll-Formed cantilever rack towers and arms have a tubular steel design. Roll-Formed will be less expensive to purchase but are limited in the amount of weight that they can support. Structural I Beam cantilever provide much greater load capacities.

Cantilever Storage Racks and all accessories are available for sale in our Fort Lauderdale, Fl. location. Cantilever storage systems and components are available for sale in both medium duty and heavy duty rack applications.

Double Side Cantilever Rack with straight 12 inch arms

|

- Cantilever Storage Racks are based on our customer's specific storage needs.

- Heavily constructed, available with many arm lengths, angles, & style options.

- Adjustable vertically in 3” increments, these racks have bolted arm connections.

- Cantilever Racking Systems increase storage capacity, make good use of limited space, and are extremely cost-effective.

- Free's up floor space and organizes your materials making your storage operations safer & faster.

- With cantilever racking systems, you multiply your vertical storage capacity by every row. Expanding your storage

space can maximize your facility’s material storage capabilities. You have the ability to extend your storage capacity without using any additional floor space.

|

Cantilever racks are the perfect heavy duty storage shelving that was designed specifically for increased storage capacity of long and bulky items,

or materials like a conduit, copper tubing, lumber, metal pipe, plywood, PVC Pipe, steel bars, and more. Not only good for long and bulky items, but a cantilever system is also excellent for storing large heavy items such as

boats, furniture, jet skis, karts, motorcycles, many large heavy items that are too large for other industrial storage solutions. A cantilever rack has the ability to increase storage capacity so many different types of products,

a cantilever storage rack is often referred to as a "specific use rack or racking" such as boat storage rack, bar storage racks, furniture storage racks, jet ski racks, lumber racks, motorcycle racks.

The flexibility of the cantilever rack makes it an extremely popular storage choice with a near-immediate return on investment.

|

|

Cantilever Racks Are Storage For: in white

|

Cantilever Racks for Lumber

|

- Rolls of Carpeting

- Electrical Wire Racks

- PVC Piping Racks

- Copper Pipe Racks

- Steel Bar Racks

- Lumber Racks

- Plywood Racks

|

- Sheet Steel Racks

- Boat Racks

- Jet Ski Racks

- Motorcycle Racks

- Furniture Racks

- Auto Salvage Yard

|

Advantages of The Cantilever Rack

Cantilever racks provide advantages that conventional shelving simply cannot match. Cantilever racks are a very efficient means of storing a huge array of items.

If you take the time to plan out how to use the racks efficiently the storage density with cantilever racks can be very high. The flexibility of use makes it an extremely popular storage choice. Using arms rather than

flat shelving it's simple to adjust arm height, angle, and spacing. Depending on the length and weight of the load, the number of cantilever arms can be changed to optimize the holding capacity. Structural steel cantilever rack

storage systems are multi-level, high-density storage racks designed to handle hundreds of different types and sizes of products with freedom from column obstructions or upright interference. Manufactured rack single sided or

double sided, Cantilever arms can be easily changed for different arm lengths or arm angles. The cantilever arm locations on the verticals easily adjust to accommodate articles of varying heights.

1. Wide-ranging Load Capacities Cantilever Systems offer the strength, durability, increased storage capacity, and layout to

store products of practically any dimension or weight. Cantilever storage racks are available to accommodate especially stressful loads, such as those common in the steel industry. In such super-heavy duty designs, the

columns are manufactured from high strength steel, then tapered to compensate for column deflection, and pre-punched on both sides for conversion from single to double-sided rack units. Further, the cantilever arm is

tapered to compensate for deflection, and the steel base is welded to the column to provide a stable foundation.

2. Accessibility Cantilever's center column design creates unlimited horizontal space purposing.

Compared to selective pallet rack designs, items are more accessible meaning easier forklift loading and retrieval. All of this equates to a significant increase in storage capacity and handling efficiencies.

3. Easy Loading and Unloading Because there are no vertical obstructions at the face of the rack,

loading and unloading product is quick and easy

4. Adjustable vertical arm spacing Bolted connections allow for easy adjustment of arms to accommodate

a wide variety of load heights

5. Modularity Easy to add on when needed. Cantilever Rack Systems modular design allows simple add on

when more storage is needed.

6. Space Efficient Cantilever Systems are excellent in limited space and are cost-effective.

Cantilever Pipe Rack

|

Cantilever Racking for a Machine Shop

|

Cantilever racking systems are a multilevel medium for heavy-duty storage with load-bearing arms that bolt to large structural steel columns.

The Steel columns anchor to weighty bases. Cantilever racks are unique among material handling racks in that they employ vertical supports attached from the rear of the rack only, with “arms” extending

from the columns at the back of the system to support loads. The framework leaves the front of the racks unimpeded by structural elements for direct pick access to goods.

Think about this, since cantilever racks have no front post or columns along the aisle to get in the way, it gives immediate access to your stock. Also, with cantilever storage every level including the base holds stock

maximizing the space being utilized. To sum it all up, a cantilever racking system is one of the most versatile and reliable storage solutions available for warehouse and industrial material handling operations.

Cantilever Racks are used by the Auto Salvage industry

|

Cantilever Racking Systems for Plywood Sheets

|

Cantilever racks are used both indoors and outdoors. By using straight arms lengths and the addition of decking, cantilever racks also can provide material handling storage racks similar to heavy duty pallet racking.

The arms provide for adjustable rack openings that easily accommodate various load dimensions. Unlike pallet racking, without a front column, there is easy access for loading and unloading. Since each storage slot is immediately

accessible it lowers your handling time and costs. Industrial Pallet Rack offers a number of cantilever systems, including Light Duty, Standard Duty, and Heavy Duty cantilever racks.

Light Duty Cantilever Rack

Cantilever light

Light Duty Cantilever Racks are designed for use in handloading situations. They’re constructed of high-strength steel columns (62,000 psi), contain bolted connections, and have welded column-to-base

connections. They’re adjustable vertically in 2″ increments. Can be built in either single or double sided configurations.

|

Standard Duty Cantilever Rack

Cantilever Standard

Standard Duty Cantilever Racks are constructed of structural steel with a 50,000 psi minimum yield. Freestanding heights up to 30-foot and 8-foot arm lengths,

arms adjust vertically in 4-inch increments. A heavy arm connection plate and bolted column-to-base connections. Can be built in either single or double sided configurations.

|

Extra Heavy-duty cantilever racking

Extra Heavy-duty cantilever racking

Extra Heavy Duty Cantilever Racks feature sturdy tapered columns and internal mast stiffeners to prevent column twists, thereby providing a safer

environment for workers to store and retrieve extra heavy items. Can be built in either single or double sided configurations.

|

Cantilever rack with wire decking

Cantilever Heavy-duty

Cantilever rack with wire decking differs from selective rack because there are no vertical obstructions from frames, resulting in higher selectivity, density, and space utilization.

With no vertical obstructions from the uprights, the wire decking spans the entire length of the row. This means extra space for you to store on and higher visibility for pickers.

|

Industrial Steel Cantilever Storage Rack

Industrial Steel Cantilever Storage Rack

We offer the widest variety of steel storage racks in the industry. Our Industrial Steel Cantilever Storage Racks are capable of storing and handling raw or finished metal and steel.

|

Heavy-duty Cantilever Rack

Cantilever Heavy-duty

Heavy-duty Cantilever Racks are constructed of structural steel with a 50,000 psi minimum yield. Freestanding heights up to 30-foot and 8-foot arm lengths,

arms adjust vertically in 4-inch increments. A heavy arm connection plate and bolted column-to-base connections. Can be built in either single or double sided configurations.

|

High-Capacity Rolled Spool Wire Storage

Cable and wire spools have unique storage requirements that cannot be accommodated well with traditional industrial storage systems such as pallet racking.

Their round, bulky nature requires a system with high weight capacities that holds them securely and safely. Dexco™ cantilever and coil racking systems from Ross can accommodate these distinctly shaped items,

and provide solutions to numerous common issues with the storage of wire spools.

|

Heavy-duty Cantlever Cable Rack

Cable racking is a cantilever rack derived system designed for the storage of cables on drums or spindles. Cable racking allows for easy cable retrieval

no matter how large or heavy your drums are. In a cable racking system, a steel rod is placed through the center of the drum or spindle to allow for horizontal storage. This also allows the cable to unravel

when pulled on.

|

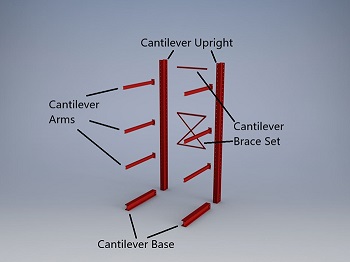

Cantilever Rack Components

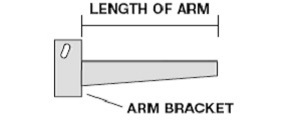

Cantilever storage rack components allow the user to design the storage rack to fit the user's needs perfectly. Choose the correct length of straight cantilever arm for flat materials

like for lumber racks, or choose the correct length inclined cantilever arm to prevent movement of round items like steel piping. Cantilever Racks can be roll formed (standard) and structural racks. Cantilever racks come both in

"Roll-Formed" and "structural". Roll-formed will be less expensive to purchase but are limited in the amount of weight that they can support. Structural Racks are made from one piece of steel and provide much greater load capacities.

Cantilever Uprights and Base One-Sided and Two-Sided

|

Cantilever UprightsThe cantilever uprights are the vertical support columns that are the strong backbone of the cantilever rack. Uprights

are made to accept both straight and inclined arms. Cantilever bases and arms attach to the uprights to complete the cantilever racking system. Uprights are available in single or double sided configurations. Single sided cantilever

racks allow material to be stored on the front side of the storage system only. With double sided uprights, storage is on both the front and backside of the upright rack. Choose either 8’, 10’, 12’ or 16’ height.

CAUTION: Some single sided cantilever uprights have holes that can bolt arms on both sides. You must consider the components of the entire system.

NEVER install arms on the backside of a single sided cantilever rack. Even if the upright has holes to hold arms on both sides, this is a very dangerous practice and should be avoided at all costs.

Cantilever Base The cantilever base is exactly what it sounds like. It is the base or foot of the cantilever Upright.

Bases are constructed of high-strength Structural I-Beam Steel. They can be used to store another level of material on the floor. They typically are the same length as the cantilever arm that is being used, but this

doesn’t always have to be the case. They do have to match whatever upright dimension you are using. Purchased as a set with the Cantilever Uprights, two base/columns are required to equal a bay. Choose your base according to base length

(arm's length can not exceed base length). If you have any more questions, give us a call.

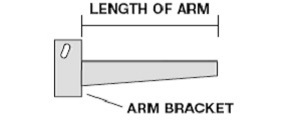

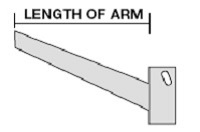

Meco 1000 Medium Duty Straight Cantilever Arms

Straight arms up to 48 inches long have minimum pitch of 3/8" per foot to compensate for deflection. 54" & 60" arms have a minimum pitch of 5/8" per foot.

|

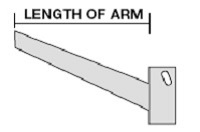

Meco 1000 Medium Duty Incline Cantilever Arms

Inclined arms have a pitch of 20 degrees or approximately 4.36 inches per foot.

|

Cantilever Arms Cantilever rack arms come in many lengths. They also are available in both straight and inclined to hold goods that could easily roll-off.

For straight arms there are arms that have a "lip" available, that attaches to the end of the arm to prevent loads from slipping off of the front of the rack arms. The cantilever rack arms attach

to the cantilever uprights at the desired heights to create the shelving levels that will be used for storage, similar to the horizontal beams that would attach to pallet rack vertical beams.

Note: For Safety NEVER have the arm lengths longer than the base length. Cantilever arms may be smaller to equal the length of your cantilever base.

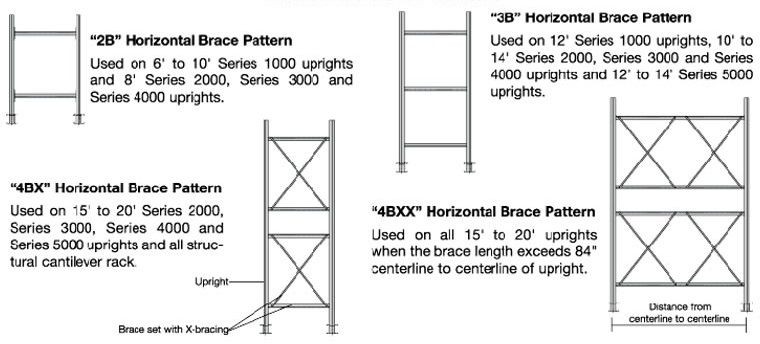

Meco Cantilever Braces

|

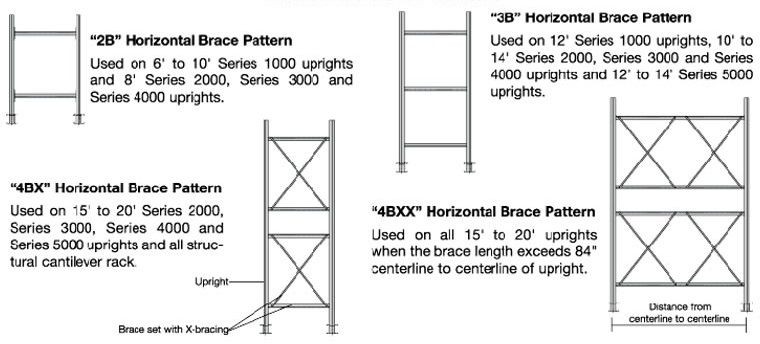

Cantilever Rack Braces X-Bracing keeps your cantilever towers braced and sturdy. Different height towers require different x-brace / horizontal setups.

Braces are structural channel members that are bolted between pairs of uprights to provide lateral stability to the cantilever racking. X-bracing is utilized to increase the lateral stability

of the taller (15' to 20') uprights. Brace lengths are measured from centerline of upright to the centerline of the next upright and are sold in sets rather than individual pieces. The load

must be supported by enough arms to prevent load deflection. Deflection may cause damage to the load being stored as well as the arms.

|

Design Your Cantilever Rack System

As with every other racking storage solution, getting it right is understanding the load. Knowing what will be on the shelves.

and the total weight is all the important factors. In order to have a safe and efficient cantilever rack system, it is first important to think about what will be stored, the size of the load (Length, Depth & Height), and the weight

capacity necessary to support your load. Whether you’re storing furniture, steel bars, pipe, lumber, or a different long and heavy item. Click the link below, for instructions on designing your cantilever rack system.

Please call (954)205-4071 (direct sales & customer service), or Email Us for pricing, availability and lead times...

Give Us a Call  (954) 205-4071

(954) 205-4071

|

In Florida Serving: Fort Lauderdale, Miami, West Palm Beach, Tampa, St. Petersburg, Clearwater, Bradenton,

Sarasota, Naples, Ft. Meyers, Ocala, Lakeland, Plant City, Orlando, Jacksonville, Tallahassee, Pensacola

Copyright © 2022 American Technologies LLC – dba Industrial Pallet Rack & Equipment® All rights reserved

Using any of the photographs on this website for commercial use is prohibited without permission from Industrial Pallet Rack® Inc.

|

(954) 205-4071

(954) 205-4071